Sliding guides

Startseite » Linear technology » Sliding guides

What are sliding guides?

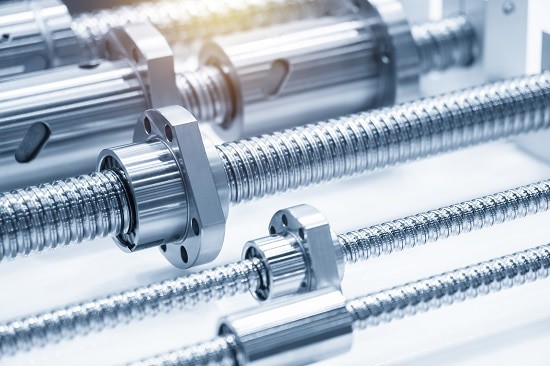

In contrast to roller guides or profiled rail guides, sliding guides do not have rolling elements such as balls or rollers. Sliding guides operate on sliding elements. The significantly larger contact surface between the individual components enables a high load capacity. This means that very high forces can be transmitted at low speeds. However, it should be noted that friction is higher than with rolling guides due to the larger contact surfaces. The large-area load distribution also allows the use of softer mating surfaces. Here, hard-coated aluminum shafts and carbon fiber shafts offer the lowest weight, whereas stainless steel shafts have the highest chemical resistance.

Advantages and disadvantages of sliding guides compared to rolling guides

Advantages

For a long service life of linear systems, it is important that friction and abrasion are kept as low as possible. In this respect, rolling guides with balls have the advantage, due to the point contact, that they are very smooth-running and the loss due to rolling friction is minimal. However, if the demands on the load capacity of linear guides become greater, more balls must be used, which not only means more friction and wear, but at the same time results in a reduced running speed due to mass inertia. This is one of the major advantages of sliding guides compared to rolling guides. The larger contact area and the associated lower surface pressure mean that less expensive and softer materials such as aluminum and non-metallic components can be used. This simplifies design, enables low-noise running and reduces energy consumption when moving entire machine parts due to the lower mass.

Other advantages of sliding guides compared to rolling guides include:

- Linear systems with sliding guides are maintenance-free.

- Sliding guides are designed for dry running. Thus, they do not cause contamination by grease or oil and are gentler on the environment.

- The damping properties of the sliding materials make them relatively insensitive to shocks, vibrations and jolts.

- Insensitive to influences such as water or chemicals.

- Usually less expensive than rolling guides.

Disadvantages

- Higher initial resistance cannot be avoided.

- Efficiency is generally lower than for linear guides with rolling bearings.

- The forces required to enable linear motion are usually many times higher for sliding guides than for guides with rolling bearings.

- In order to keep sliding friction as low as possible, linear plain bearings with a small interference fit must be used. Preloaded units with rolling bearings therefore have significantly higher rigidity.

At PACH Systems you can obtain various sliding guides. For this purpose, we work together with our long-standing suppliers. Please let us know your wishes and requirements via our contact form. We will be happy to provide you with a non-binding offer or contact you to discuss the details.