Static Seals

Startseite » Sealing technology » Static Seals

Static seals are used to separate two spaces with different contents. This is to prevent the exchange of solid, liquid or gaseous elements between two components, or to reduce it to a limited extent. In contrast to dynamic seals, the surfaces to be sealed do not move relative to each other. The two surfaces are therefore in constant contact with each other.

The requirement for the lowest possible frictional forces, which are intended to prevent energy loss, does not apply to static seals, which is why the contact forces between the sealant and the parts to be sealed can be selected to be higher. This results in a higher sealing effect.

In the case of static gaskets, the minimum required and maximum permitted pressure must be taken into account. These requirements may vary depending on the gasket type, material and manufacturer. The minimum pressure must be selected so that the static seal can withstand the pressure to be sealed under all operating conditions, e.g. temperature, deformation or vibrations. However, the maximum pressure must not be exceeded, otherwise the seal will be destroyed.

The minimum required pressure ensures that even microscopic gaps between the seal and the parts to be sealed become so small that the substance to be retained can no longer penetrate.

With the help of the parameters minimum required and maximum permitted pressure as well as the pressure to be sealed, a preselection of the static seals can already be made. This preselection can be specified by further selection criteria:

- Chemical and thermal resistance

- Required safety and leakage classLeckageklasse

- Target service life

- Tightness under deformation and vibration

- Seal geometry, installation space

Within static seals, there are seals that are pressed on purely by external forces. These include, for example, flat gaskets. On the other hand, there are static seals that are activated by the system pressure (e.g. O-rings) and for which the sealing pressure increases in line with the system pressure. Such seals only have to be precompressed during assembly. Since the sealing pressure increases in line with the system pressure, it is always higher than the pressure to be sealed by the amount of the precompression.

We have the following static seals in our assortment

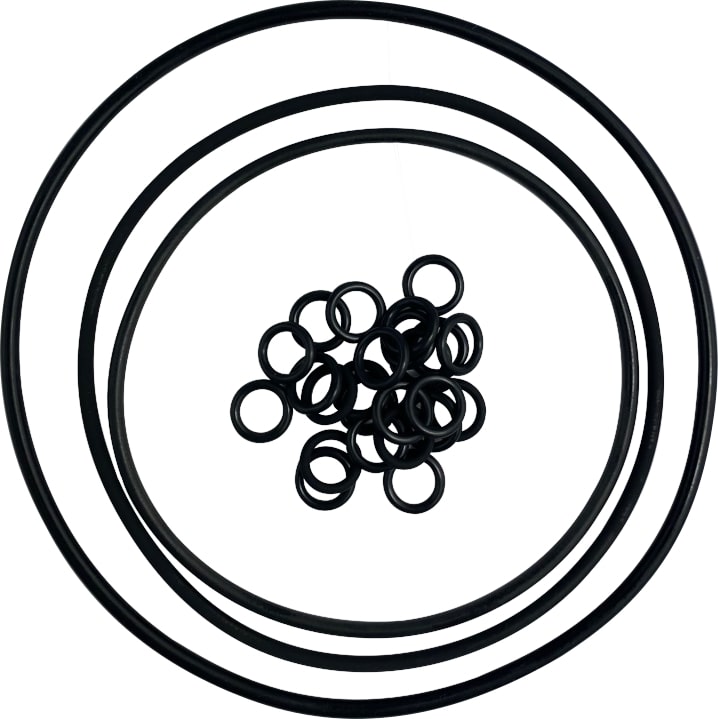

O-rings and X-rings

Circular rings made of elastomer materials with a circular cross-section, known as O-rings for short, are the most versatile static seals. O-rings are capable of sealing pressures of up to 1000 bar. This property makes them the most commonly used seals in engineering. O-rings are pressure-activated seals, which is why they only need to be lightly precompressed during assembly. In the operating condition, the pressure of the component to be sealed then reinforces the deformation of the O-ring, creating a higher sealing effect. The sealing pressure of the O-ring always increases equally with the system pressure, which is why the sealing pressure is always higher than the pressure to be sealed by the amount of the precompression. The gap to be sealed should be as small as possible in the case of O-rings, because if the pressure applied is too high, the O-ring can slip into the gap on the side facing away from the pressure and be destroyed after some time. If the sealing gap cannot be made narrow enough due to certain requirements, it can be reduced by using a back-up ring. The back-up ring has no sealing function in this case, but enables the O-ring to provide a durable and damage-free sealing function.

O-rings are primarily suitable for static sealing, but in a few cases they can also be used as dynamic seals in pneumatics or hydraulics. However, it must always be noted that the application is limited to low pressures and speeds.

X-rings are comparable to O-rings in their application and handling. The advantages of X-rings are:

- Security against twisting. The four-lip profile better prevents rolling of the seal in the groove.

- Geringe Reibung. X-Ringe benötigen im Vergleich zu O-Ringen eine geringere Vorspannung. Kleinere Anpresskräfte führen dabei zu weniger Reibung, was wiederum einen geringeren Verschleiß und eine höhere Standzeit begünstigt.

- Low friction. X-rings require less preload compared to O-rings. Smaller contact forces result in less friction, which in turn promotes less wear and a longer service life.

- Compared to the O-ring, the X-ring has a double sealing function. It requires less precompression, which leads to reduced friction during dynamic use.

Flat Gaskets

Flat gaskets are used to seal two smooth sealing surfaces, which is why they are classified as contact seals. They are not pressure-activated seals and are pressed onto the machine components solely by external forces. It is important to ensure that the pressure is as uniform as possible in order to reliably prevent liquids and gases from escaping. Flat gaskets are used primarily when components are detachably connected to each other by screwed joints, as is the case, for example, with flange or housing connections. The aim is to prevent the respective medium from escaping from the hollow body to be sealed. Flat gaskets are offered in various thicknesses and can be cut to size according to the area to be sealed.

Due to the wide range of applications for flat gaskets, they are available in many materials and material combinations. A distinction is made between hard, soft and multi-material gaskets. Hard gaskets are usually made of soft metals such as copper, lead or aluminum. Soft gaskets are mainly made of paper, cardboard, rubber, various plastics, graphite and PTFE.

Bonded seals

Bonded seals are metallic flat gaskets used for static sealing of bolted and flanged joints. These gaskets consist of a washer and a vulcanized, trapezoidal and rubber-elastic sealing bead. The sealing effect is achieved by tightening the bolted joint. In the process, the sealing lip presses against the flat surfaces to be sealed, thus creating a closed plane.

Closure caps

Closure caps are used in mechanical engineering to close housing bores and at openings of shaft or axle inlets. Closure caps have an elastomer outer ring and a metal partially coated stiffening ring.

PACH Systems offers you a wide product range of different static seals. For this purpose, we cooperate with our long-term partners. Please let us know your requirements via our contact form. We will be happy to provide you with a non-binding offer or contact you to discuss the details.