Deep groove ball bearings

Startseite » Rolling bearings » Deep groove ball bearings

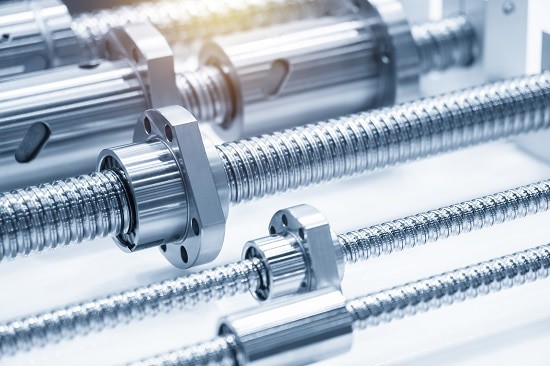

Deep groove ball bearings are the most frequently used rolling bearings of all, which is why they offer a good price-performance ratio and a wide variety of types and designs. Deep groove ball bearings are versatile and insensitive in operation as well as easy to maintain. Furthermore, they are self-retaining and predestined for high to very high speeds. The relatively small contact zones between the balls and the groove result in minimal friction surfaces and thus reduce rolling resistance. To further reduce rolling friction, deep groove ball bearings are usually lubricated by oil or grease. Thus, a lubricating film forms between the ball and the groove during the rotational movement, which prevents direct rolling contact (dry running).

Modern rolling bearings are already provided with a suitable rolling bearing grease by the manufacturer. As standard, deep groove ball bearings are held and guided in a specific position by means of a cage. An exception are full complement deep groove ball bearings, which do not have a cage and thus contain the largest possible number of rolling elements. The higher number of rolling elements enables a higher load capacity compared to cage-guided deep groove ball bearings. The special feature of this type of bearing is that, in addition to radial loads, they can also support axial loads in both directions. This is made possible by the deep raceways and the narrow osculation.

A disadvantage characteristic of ball bearings in general is that the load that deep groove ball bearings can support is limited due to the point rolling element contact. Furthermore, the expected life expectancy is lower in contrast to other bearing types. The bearings, which are simple in design, easy to maintain in operation and sensitive, are available in single or double row as well as open or sealed.

Single row and double row deep groove ball bearings

Single row deep groove ball bearings

Single row deep groove ball bearings are available in many designs and dimensions. Open single-row deep groove ball bearings are particularly suitable for the highest speeds due to the low frictional torque, whereas bearing designs with gap seals are suitable for high speeds.

Double row deep groove ball bearings

The design of double-row deep groove ball bearings corresponds to a pair of single-row deep groove ball bearings. Compared to single-row deep groove ball bearings, double-row deep groove ball bearings have two running grooves with one row of balls each. This type of bearing is needed when the load capacity of single-row deep groove ball bearings is insufficient. Compared to single-row deep groove ball bearings, they have the same bore and outer diameters, but are a little wider, whereby they have a significantly higher load capacity.

Sealed deep groove ball bearings

The common deep groove ball bearings are also available with cover or sealing washers on one or both sides as standard (see above). The sealing designs here range from a low frictional torque to a higher frictional resistance. Seals with low frictional resistance use the principle of a narrow gap seal. Seals that have a higher frictional torque are designed as a sliding seal with a high sealing effect. Bearings sealed on both sides are maintenance-free and lubricated for life.

Axial deep groove ball bearings

Axial deep groove ball bearings are available as single or double direction bearings, which are designed exclusively to support axial loads and must not be subjected to radial loads. Due to their design, axial deep groove ball bearings are not self-retaining. The installation of the individual bearing parts is carried out separately and is therefore very simple. Axial deep groove ball bearings are particularly suitable for bearing positions that are subjected to high axial loads on one or both sides, whereby the axial load carrying capacity requirements are not so high that even higher load carrying axial cylindrical roller bearings are required.

Axial deep groove ball bearings are multi-part bearing units which, due to their design, are not self-retaining but are easy to mount and belong to the group of axial ball bearings. The bearings consist of a shaft locating washer, one or two housing locating washers, one or two ball and cage assemblies and a washer and can be installed separately. Both the shaft locating washer and the housing locating washer have raceways with a defined curvature for guiding the balls, in which the rolling elements rotate. The balls are held by a cage. As standard, these are sheet metal cages made of steel or solid brass cages.

Single direction thrust ball bearings absorb axial forces in one direction and support the shaft to one side. They consist of a shaft washer and housing washer with a ball and cage assembly between them.

Double direction thrust ball bearings absorb axial forces in both directions and guide the shaft in both directions. They consist of a shaft locating washer, two housing locating washers and two ball and cage assemblies. It should be noted that axial deep groove ball bearings react sensitively to angular errors. Angular errors and misalignments between shaft and housing can be compensated for by the bearing in conjunction with a spherical housing washer and support washer.

PACH Systems offers you a wide product range of different deep groove ball bearings. For this purpose, we work together with our long-standing partners. Please let us know your requirements via our contact form. We will be happy to provide you with a non-binding offer or contact you to discuss the details.