Shaft Guidance Systems

Startseite » Linear technology » Shaft Guidance Systems

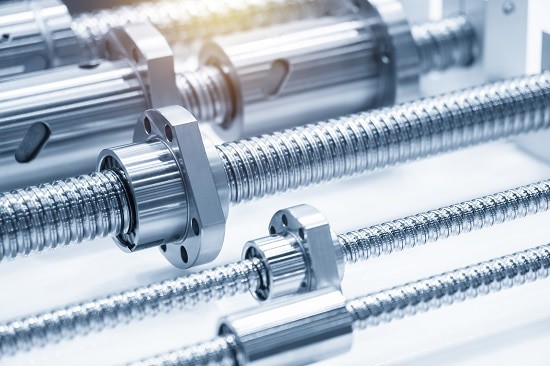

Shaft guidance systems or circular guidance systems can generally be described as rolling bearings for unlimited longitudinal movements. Shaft guidance systems can be used in specific variants for rotational movements or also for short and fast stroke movements. The special feature of shaft guidance systems is that they are robust, reliable, powerful and very economical due to their simple design. The design of shaft guidance systems is based on hardened guide shafts in combination with various linear ball bearings or linear ball sleeves, thus opening up numerous variation possibilities. In addition to the type of bearing, the guide elements can also be selected from a wide range. Mounting the guide shaft on various shaft supports and using open guide elements creates further diversification options. Circular guides with shaft support provide an inexpensive and robust alternative to profiled rail guides.

Linear ball bearings

Linear ball bearings or ball bushings are special ball bearings with an unusual axial ball recirculation. Their purpose is not to support a rotating element, but to guide the translational, i.e. linear, movement of a machine element along a cylindrical shaft with as little friction as possible. Consequently, a differentiation into locating and non-locating bearings, as is usual for rolling bearings, is pointless in the case of linear ball bearings.

The respective permissible load of a linear ball bearing depends on the number of supporting rows of balls. Instead of an outer ring, today’s linear ball bearings have several raceway plates on the outer diameter of the bearing on which the balls roll in the linear bearing. The raceway plates of modern linear ball bearings are located in a plastic housing, which also serves as a ball cage and performs the function of ball recirculation. Here, the balls do not run on an inner ring, but directly on a shaft made of precision steel. Furthermore, linear ball bearings are available both without and with one or two-sided sealing at the end faces.

Similar to rolling bearings, linear ball bearings are standardized and offered in different dimensions. Various ISO series define the exact inner and outer diameters as well as the lengths of these bearings. As a rule, linear ball bearing sizes are defined according to the inner diameter.

In linear ball bearings, the effective load rating is determined by the position of the load direction in relation to the position of the rows of balls. The lowest load ratings result from the “apex position” of the rows of balls. On the other hand, the maximum load ratings are possible with a so-called “symmetrical position” of the rows of balls. In the event that the bearings cannot be installed in a directional arrangement, the maximum load rating can be used. If this is not possible or the load direction cannot be determined exactly, the minimum load rating must be assumed.

Usage

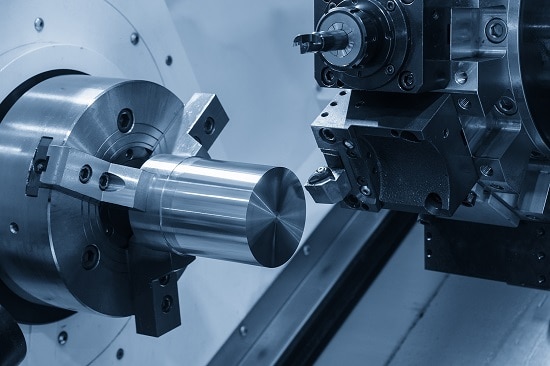

Linear ball bearings are mainly used in technical applications such as computers & peripherals (e.g. scanners), automatic registration systems, 3D measuring equipment (e.g. multi-spindle drilling machines), 3D printers, presses, machine tools and machining centers including their doors. Furthermore, linear ball bearings can be used in the construction of linear tables and other sliding devices. For example, at the foot under the armchairs of the front rows in the plenary hall of the German Bundestag there are corresponding displacement units based on linear ball bearings, which enable the back and forth movement on the armchair.

Other series of the shaft guidance systems:

Linear housing units

- Delivery in closed, slotted or open design

- The load rating of the installed linear bearing must be considered from each direction

- The installation of the housing units is possible upright, suspended or also sideways

- The material of the housing is die-cast aluminum

Precision guide shafts

- Hardened and ground guide shafts

- Suitable for weight-reduced constructions

- Precision shafts can be provided with radial and axial threaded holes for fastening purposes

PACH Systems offers you a wide product range of different shaft guidance components. For this purpose we cooperate with our long-term partners. Please let us know your requirements via our contact form. We will be happy to provide you with a non-binding offer or contact you to discuss the details.